Our Vision:"To deliver the best possible products for the best possible price and quality."

How to control our quality?

1. European Standard.

To maintain high-quality standards, we use top-tier imported valves and pumps from EU brands (Denmark and Italy). This not only enhances our competitiveness but also enables users to easily source spare parts locally, saving both time and costs.

Our design and manufacturing processes strictly adhere to European standards, including EX/ATEX requirements. We utilize high-strength steel plates, such as HG70/Q690/DH36 and AH36, which meet the GB/T712 and GB/T 16270-2009 standards.

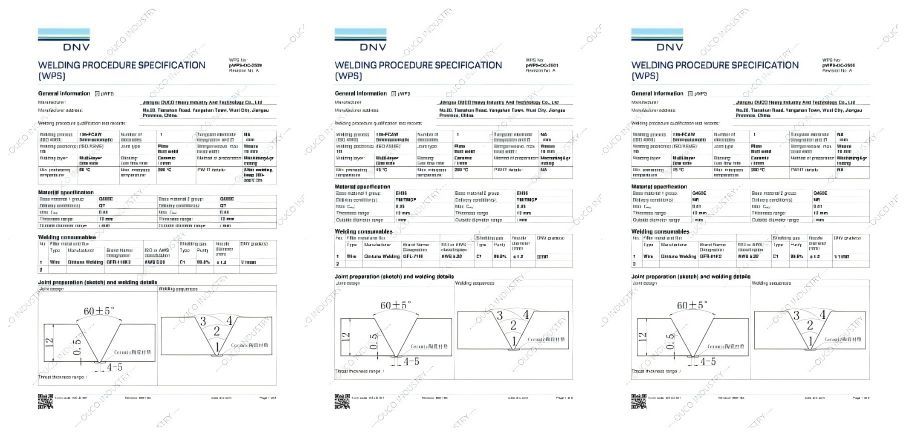

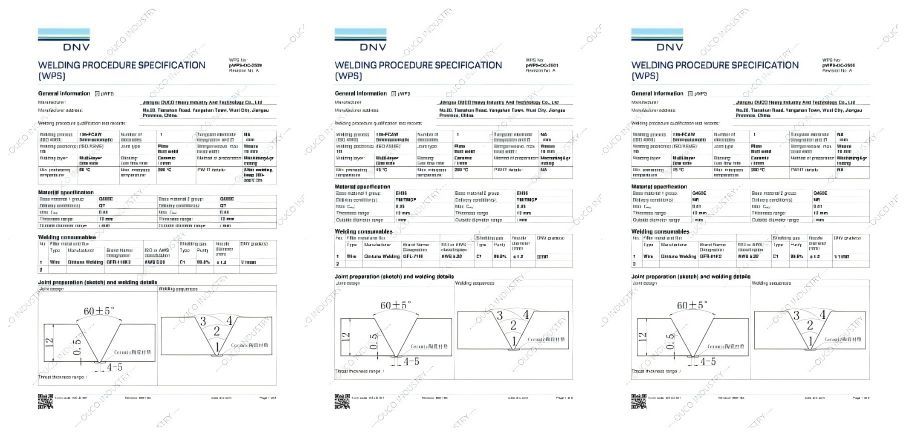

2. Flaw Detection.

We follow a certified Welding Procedure Specification (WPS) approved by ABS, CCS, BV, and RS (2025 version). All welded surfaces undergo 100% non-destructive testing to ensure smooth and reliable welds, such as RT, DP, and UT testing.

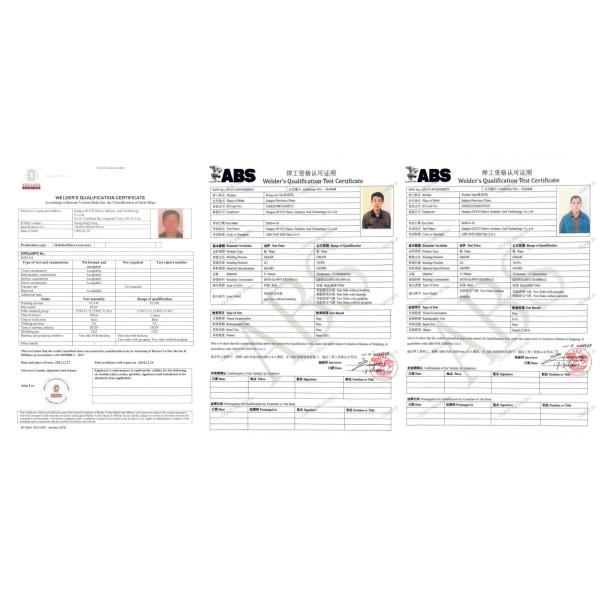

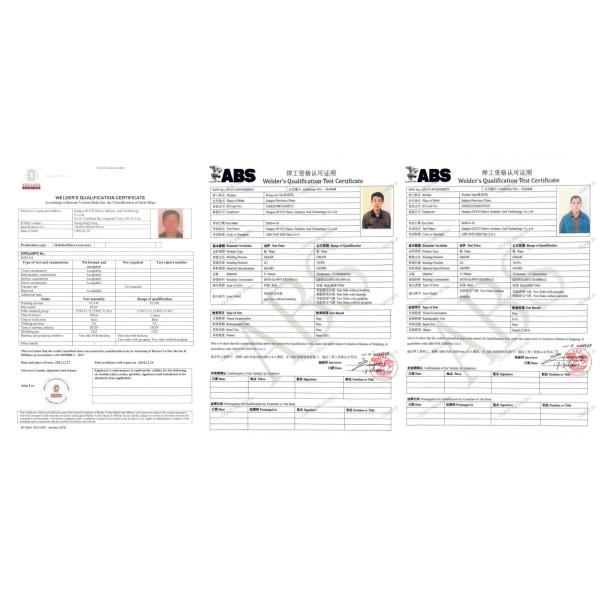

3. Internationally Certified Welder.

In order to ensure the welding quality of the product structure, each welder of our company has the qualification of international certification.

4. Painting Process.

Before painting, we perform sandblasting to the SA2.5 standard, ensuring the paint adheres firmly. Following this, we apply three or more layers of paint, in compliance with CX Marine Rules, to protect against seawater corrosion and significantly extend the equipment's service life.

5. Final Testing.

Finally, we conduct crane tests on a platform simulating real marine conditions (5° Trim, 2° Heel). This ensures the crane's stability and reliability, verifying its performance under wind, waves, and swinging motion to prevent safety incidents in actual use.